Innovation

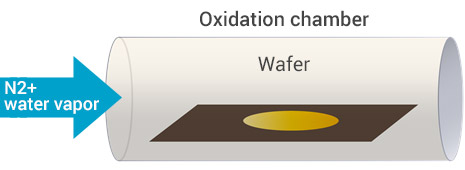

Existing technology

Wafers are processed one by one.

- Oxidation aperture sizes are controlled by the process time.

- Issues on non-uniform oxide aperture size on a wafer and on low reproducibility between wafer to wafer

- Even with in-situ monitoring tools, it is not possible to solve the issues on non-uniform oxide aperture size on a wafer.

- Issues on the stable quality control and improving production yields of VCSEL products.

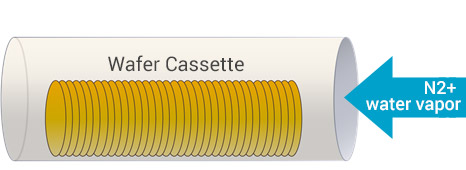

RayIR technology

Multiple of wafers can be process at once.

- A physically limited and self-terminated oxidation process allows stable and uniform processes.

- Able to achieve uniform oxide aperture sizes on the wafer, wafer-to-wafer, and batch to batch process.

- Allows dramatic improvement in VCSEL production yields.

- Improved production throughput is possible as well.

- Expect to improve the VCSEL chip reliabilities especially on high power applications.